Smal Guide for Circular Barcode ... ( for all and Nages )

comments and your experiences are appreciatedBy

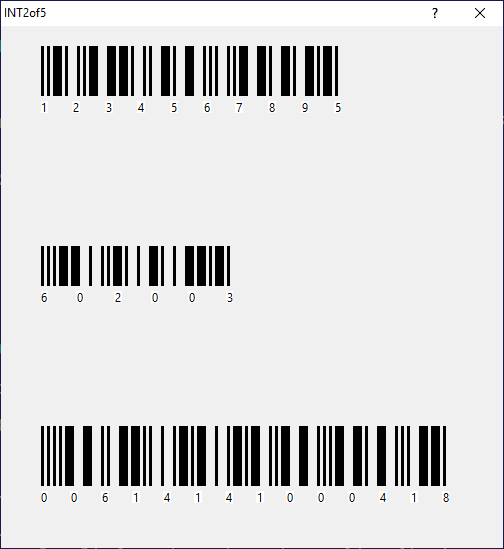

linear we mean a bar code as we are normally used to seeing it: an alternating series of straight, white and black lines, of different thickness, usually accompanied by an underlying writing in legible characters by a human being.

Currently there are several 1-D bar coding standards, used with different frequencies depending on the advantages and disadvantages deriving from the adoption of a coding system with respect to the other. All the symbologies foresee the creation of a rectangular figure, which is read by sliding or scanning, creating an ideal line that crosses the symbol, perpendicularly or at an angle close to 90 ° with respect to the bars

If the scan line does not completely cross the bar code, for example due to a limited angle with the vertical lines printed, the code is not read:

This involves some constraints on the positioning of the code itself, since the reading device must be on the bar code passing directive and with the reading line perpendicular to it. To overcome this, raster devices have been introduced (with multiple parallel reading lines), with oscillating mirror, or with various angled mirrors so that the code can be read regardless of the orientation with which it appears.

A

circular code is readable by the same tools reserved for reading traditional bar codes, but has some advantages:

reading is independent of the orientation of the symbol, as the reading range can affect the symbol with any angle (provided that it does not always cross the center);

the symbol is in effect the 360 ° distribution of two scan lines of a rectangular bar code, separated by an overflow equal to 2 times the radius of the innermost circle; this feature can avoid the purchase of scanners with multiple reading directives, it greatly simplifies the acquisition of the bar code through sliding devices and allows printing of higher density codes, as the vertical redundancy increases

it can be used to label media, such as CD-ROMs and DVDs, which require a perfect label balance;

it has sufficient redundancy to ensure that the code is read in virtually all cases, even if the surface is partially damaged;

as the overflow increases (central area) the need to center the crossing of the beam decreases and therefore it is possible to use standard laser readers instead of raster readers (for fixed stations); this happens because the lateral deformation of the bars is compensated in large part by the reading instruments, which (in laser and ccd technologies) already provide for the detection of symbols even on partially curled or bent surfaces.

Since the interpretation of the bar code by the reading instruments takes place when the overflow zone is detected, the reading line can in any case completely cross the symbol, following a diameter, without causing a double reading of the encoded content.

The use of circular bar codes in the labeling of CD-ROMs in general and DVDs in particular is decidedly crucial: DVDs, for example, can be printed on both sides, leaving very little space for marking.

On the other hand, in the rental of such media it is essential to identify the disk both for cataloging reasons and to avoid fraud.

The application of any unbalanced mark on a CD-ROM or DVD, such as a traditional bar code label (rectangular), would lead to an imbalance in the support: this imbalance introduces an interference in the reading of the information that can deteriorate the quality of the audio / video reproduced, limiting the speed in extracting information (or inhibit it altogether), causing noisy resonances in the mechanics of reproduction systems (shortening the life of such devices).

By using our class with a suitable resolution, it is possible to insert a bar code up to 8 digits into the central crown of the DVD, without altering the balance of the disc, without covering useful information for reproduction and without altering the contents of the screen-printed side ( if present).

Our class also allows us to produce codes in which each semicircle contains one half of the information to be encoded, possibly supplemented by standard linear codes.

No less interesting is the use in the industrial field, for example to label boxes that can be stored in various ways. These packages can be identified on three sides by applying a single label.

In this case, a quadrant of the symbol is removed (by means of a suitable die cut), covering it by 270 °, and providing for its application on a corner of the neck to be identified:

Hoping that this little guide was welcome, I greet you all good evening